LED power supply is one of the core components of LED lighting. Understanding the basics of power supply is necessary to source the right lighting system and optimize overall performance.

This comprehensive buyer’s guide takes an in-depth look at the different types of power supplies, explaining the principles and parameters, as well as selection considerations, using LED strip light switching power supply as an example. Topics such as wattage calculations, power supply types, and installation tips are covered.

Armed with this essential knowledge, you will be able to make an informed decision when purchasing the power supply for your LED light.

An LED power supply, also known as an LED driver, is a device that converts and regulates power from a power source. The process includes a combination of circuits such as rectification, filtering, boosting, and constant current to convert the AC power supply into DC power that meets the working requirements of LED lights.

Its main role is to convert the input voltage into a DC power supply suitable for LED light-emitting, to ensure that the electrical performance of LED lighting is met.

The LED driver is a power supply designed for LEDs that regulate current, convert voltage, and provide protection. It ensures the safe, efficient, and reliable operation of the system.

LED beads are very sensitive to current. If the operating current exceeds the rated current, it will be damaged, while too little current will result in insufficient brightness.

Therefore, the LED driver regulates the current flowing through the LED beads to ensure that they are optimally matched to the current.

Most LED drivers convert household AC voltage (120V or 240V) to a low DC voltage suitable for proper operation of the LED beads. Typically 5V, 12V, 15V, 24V, 36V, or 48V depending on the design of the LED fixture.

A good LED driver has a high energy conversion efficiency, typically 80% to 95%. This means that most of the input power is converted into usable energy with minimal heat loss.

A linear topology is used to regulate the output voltage and current, which can be divided into two phases: the current regulation phase and the current stabilization phase.

In the current regulation stage, the input current is converted to the desired current level using a resistive regulator or an electronic component. Common regulators are linear regulators and switching regulators.

Linear regulators use linear control means to change the output current by adjusting the size of the resistance.

A switching regulator uses switching control means, by adjusting the switching frequency and operating cycle to change the output current.

It is characterized by simple circuits, small size, and low cost, but the system efficiency is low.

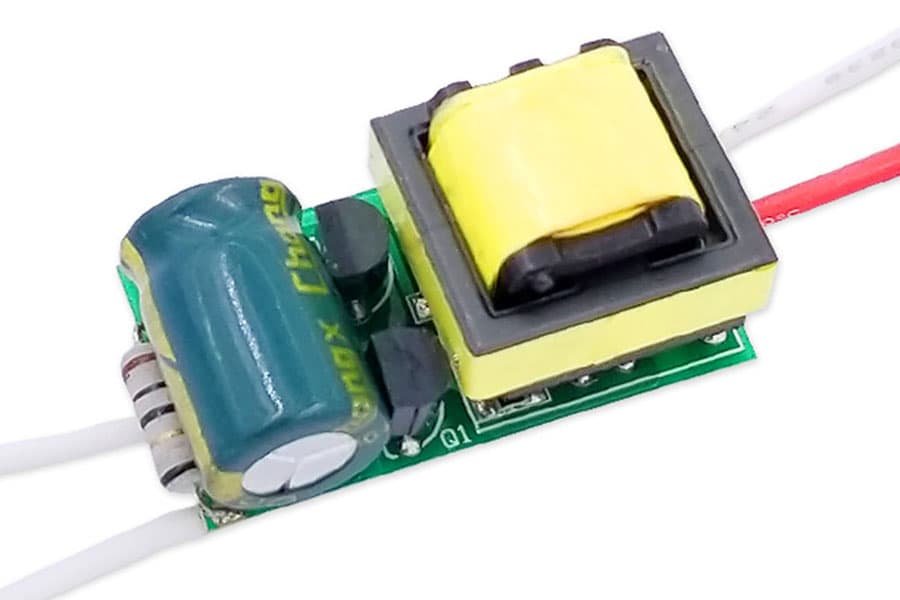

A switch mode LED driver, also known as an LED switching power supply, uses a switching converter topology to regulate output voltage and current. Its core components include switching controllers, inductors, switching elements (e.g., MOSFETs), feedback resistors, input filters, and output filters

The working principle of switch mode LED driver is to control the on-off of switching elements (such as MOSFET) through high-frequency switching to convert the input DC or AC power supply into a high-frequency AC power supply, then step down the voltage through the high-frequency transformer, and finally converted into a stable DC power supply through rectifier and filtering circuit to supply the LED beads.

The constant voltage driver mainly controls the brightness of the LED by keeping the output voltage constant. It uses a switching power converter to make an isolated constant voltage power supply with a constant and adjustable output voltage.

This type of drive is usually used in applications that require stable output voltage, such as building exterior lighting like LED light bars or landscape lighting.

A constant current driver controls the brightness of the LED by keeping the output current constant. In LED light applications, the constant current circuit adjusts the current so that the brightness of the LED light is stable and not overloaded.

The constant current drive circuit consists of two main parts, a current source and a constant current circuit (current limiter).

This type of drive is typically used in applications that require precise control of the LED current, such as lighting design and stage lighting.

This is an LED driver that adjusts the output voltage and current by creating a program. It is ideally suited for precise lighting control applications that require a compact, scalable, easy-to-power, and high-linearity power supply.

Next, we take the switching power supply used in LED strip light as an example to explain the principle and parameters

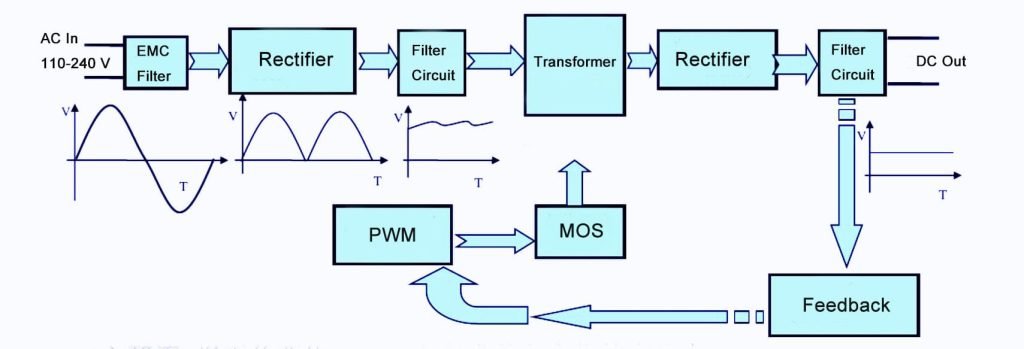

LED switching power supply through the rectifier, filtering, switching conversion, transformer, output rectifier, output filtering, and voltage regulator steps, the input AC power will be converted into stable DC power for the normal operation of the LED lamp.

Power refers to the amount of work done by an object in a unit of time, that is, power is a physical quantity that describes the speed of work. The amount of work A certain amount of time, the shorter the time, the greater the value of power. The formula for power is power = work/time.

The specific input voltage of the drive under the specified operating conditions. Usually, we refer to the full voltage as 90-264VAC, but there are also low-voltage 90-130V and high-voltage 176-264V, in order to meet the requirements of different countries, regions, and customers. There are also DC inputs, mainly 12V, 24V, 36V, 48V and so on.

Input voltage frequency refers to the frequency of the sine wave of the grid input voltage. The frequency is not the same in different countries and regions, usually, the frequency used is 50Hz and 60Hz, with a permissible deviation of 3Hz.

In an AC circuit, the cosine of the phase difference between voltage and current is called the power factor. Numerically, the power factor is the ratio of active power to apparent power.

The power factor is a measure of the efficiency of electrical equipment. A low power factor means that the reactive power of the circuit is high, the equipment is underutilized, and the line supply losses are increased.

For example, a PF value of 0.5 of 20W lamps need the grid to provide 40W of power in order to work properly, and the excess of the 20W power loss in the household meter will not show but also did not play a practical role, which increases the power supply loss of the line..

The input voltage regulation reflects the power supply’s ability to adapt to the power grid. It indicates the relative change of constant current driver output current (or constant voltage driver output voltage) caused by the change of input voltage when all other influences (temperature, etc.) remain unchanged, and it is also called linear adjustment rate.

It is the ratio of output power to input power; i.e. conversion efficiency = (timely output power provided by the power supply for the LED/immediate power input from the power supply) x 100%.

The magnitude of current fluctuation during power supply operation. Expressed as: (measured value – demand value) / demand value;

LED drive power supply should generally be controlled within ± 5%, so as to reduce the current changes on the LED light failure and the impact of the whole lamp power.

In all other influences remain constant, due to changes in the load caused by the constant current driver output current (or constant voltage driver output voltage) of the relative amount of change. Because the LED voltage frequency conversion control will change with the temperature changes, lamps, and lanterns in the use of the process relative to the power supply output is a change in the load, so the power supply must be able to adapt to this change.

Under the condition of rated minimum input voltage, 90% of the period from AC power on to the establishment of constant current output rated current (or constant voltage output rated voltage). Generally, less than 5W requires startup time less than 0.5S, 5W-30W less than 1S, 30W or more than less than 3S.

Start-up time is mainly considered the low-temperature characteristics of the power supply and is one of the important parameters of outdoor lamps.

The IP rating is the level of protection of the housing of an electrical device against the intrusion of foreign objects, derived from the International Electrotechnical Commission (IEC) standard IEC 60529. The format of the IP rating is IPXX, where the first digit stands for the level of protection against the ingress of solid foreign objects, and the second digit stands for the degree of waterproofing.

Commonly used for indoor power supplies IP20: Protected against solid foreign objects larger than 12.5 mm in diameter but not waterproof;

Outdoor power supply IP67: completely prevents the intrusion of foreign objects and dust and short-term intrusion of 1-meter deep water does not hinder the normal operation of the power supply.

Indoor power supply -20~45℃, outdoor power supply -30~60℃;.

For LED driver power supply, low temperature is mainly considered start-up time, and high temperature is considered stability.

Indoor power supply -30~70℃, outdoor power supply -40~90℃;

After 72 hours of storage, the product can still work normally.

Voltage withstands test:

Class I luminaire power supply: 1500VAC, 10mA, 60S.

Class II luminaire power supply: 4000AC, 10mA, 60s.

basic insulation ≥ 2MQ; double or reinforced insulation ≥ 4MQ

The grounding resistance of the power supply of Class I lamp is less than 0.5 ohm, and that of industrial and mining lamp, street lamp, track lamp, and other movable lamp shall not be greater than 0.2 ohm.

Class I luminaire power supply: 1500VAC, 10mA, 60S;

Class II fixture power supply: 4000VAC, 10mA, 60S;

Class HI fixture power supply: 500VAC, 5mA, 60S.

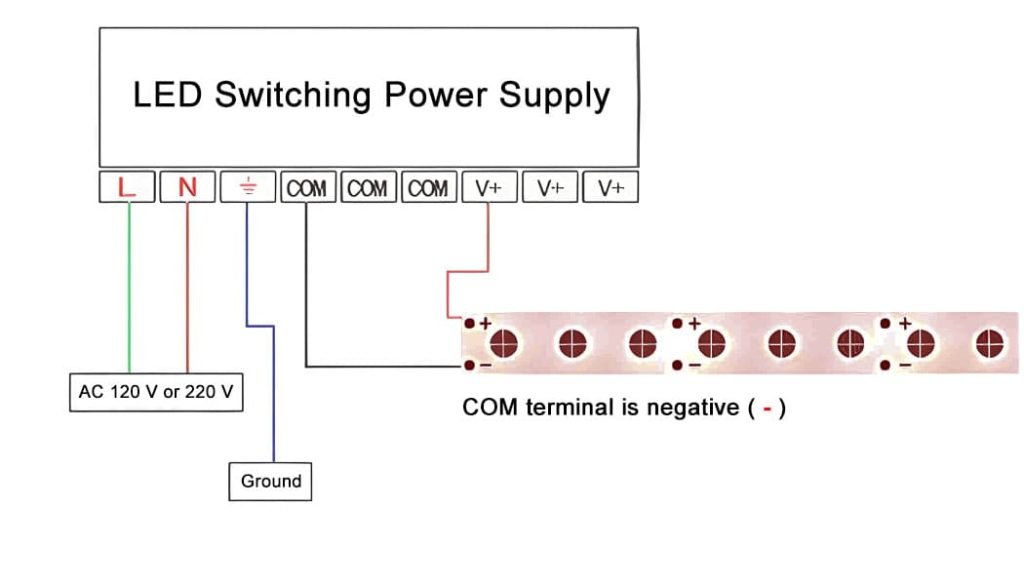

Take LED strip light as an example, first, determine the voltage requirement of the LED light strip: usually you can find clear labeling on the strip, such as DC12V or DC24V.

For example, if the strip is 12VDC, the power per meter is 12 watts, and the total length is 5 meters, then the total power is 60 W. In this case, you need to choose a constant voltage driver with an output power greater than 60 W, taking into account the driver to leave about 20% margin to ensure its stable operation. That is, a power supply of about 60×1.2=72W is needed.

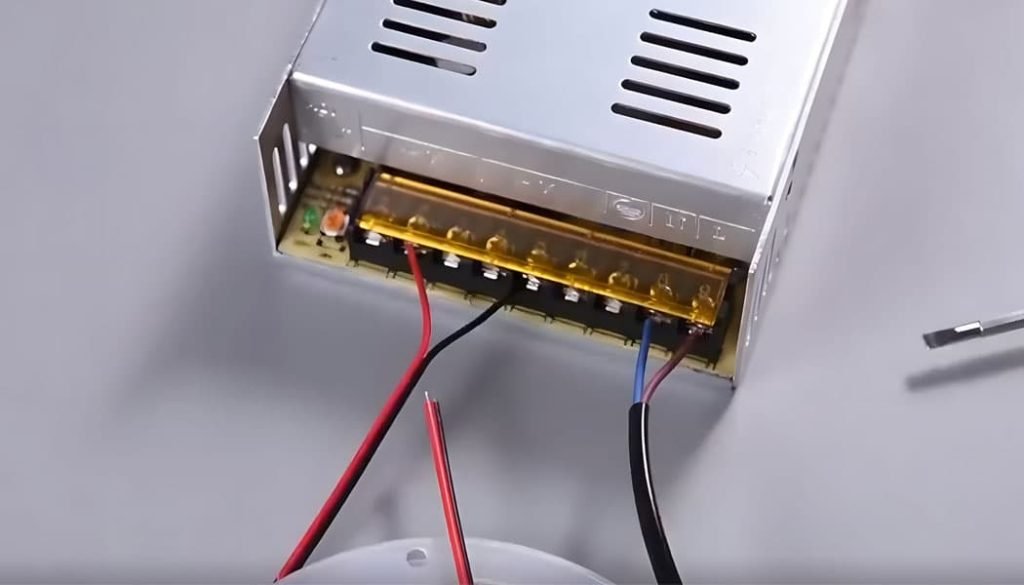

Take DC12V flexible strip light as an example.

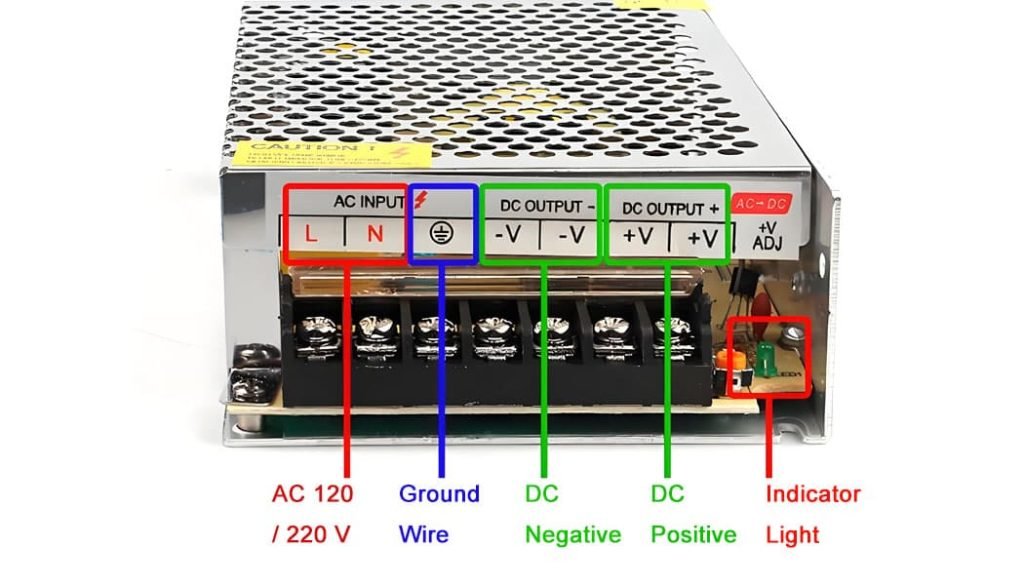

Step 1, the positive and negative poles of the power cord were connected to the positive and negative poles of the 120V (220V) input terminals of the power supply.

Step 2, the red and black wires of the LED strip light are connected to the positive and negative terminals of the 12V output terminal of the power supply.

Step 3, finally the power plug into the AC120V (220V), test whether it works properly.

In summary, having a basic knowledge of LED power supplies is critical to ensuring the proper fit and longevity of your LED lighting system. By familiarizing yourself with the various types, parameters, and installation techniques, you can effectively navigate the complexities of powering LED lighting and make informed decisions before making a purchase.

LED Panel Lights: The Preferred Solution for Hospital Lighting The right hospital lighting design plays a crucial role in providing visibility, enhancing color rendering, minimizing glare, promoting patient well-being, and…

Professional Power Amplifier Purchasing Guide Whether for commercial or home use, professional power amplifier is a kind of audio equipment with high cost performance. LayviKay, as a reliable audio factory…

Some Basic Elements of 18650 Battery for Solar Lights The 18650 rechargeable battery is a crucial component of many solar LED lights. Selecting an appropriate 18650 battery is especially important…

Network Audio Amplifier Guide Tips What is Network Amp? A Network Amp, aka IP-based audio amp or network audio amp, is an audio device that merges the functions of an…

Can You Charge A Solar Panel With An Led Light? Solar panels and LED lights have revolutionized the way we harness and utilize energy. Solar panels, with their ability to…

How To Purchase A Right LED Panel Light? LED panel light is a popular choice for indoor lighting application. It is designed to provide a bright, even, and energy-efficient lighting…