LED panel lights have become an increasingly popular lighting solution for residential, commercial, and industrial applications. In this article, we will explore the key factors and best practices involved in manufacturing high-quality panel lights, from selecting the right components to implementing rigorous testing and inspection procedures. By following a comprehensive approach, purchasers can have confidence in the reliability and durability of LayviKay LED panel lights, ultimately leading to safer and more efficient lighting environments.

LED panel light is a flat and lightweight fixture that consists of multiple light-emitting diodes (LEDs) placed in a grid pattern. It is a type of energy-efficient lighting used for both commercial and residential applications.

There are two construction types based on different thicknesses, one is back-lit and the other is edge-lite.

Edge-lit panel light consists of a diffuser plate, light guide plate, aluminum frame, and back plate. While the back-lit type panel light has no light guide plate. For more about the panel light construction, please visit: https://www.layvikay.com/how-to-purchase-a-right-led-panel-light/

Normally, they come in various sizes and shapes like square, rectangular, or round. All of these panel lights are designed to fit into various spaces to replace traditional fluorescent or grille lamps.

High-quality LED panel lighting offers a range of benefits that can enhance our everyday lives. For starters, they provide bright and uniform illumination, evenly spreading light across a room and reducing shadows.

Additionally, high light efficiency is one of the characteristics of high-quality panel lights. Normally, the light efficiency of the whole lamp needs to be more than 150lm/w. Here to point out is the whole lamp light efficiency, not a single bead light efficacy.

Moreover, high-quality panel light uses an isolated driver power supply, so the safety will be higher. Electrolytic capacitors for switching power supply also need to be designed with well-known brands and sufficient capacity. It can ensure the driver’s life longer, and minimize maintenance costs.

Low-quality LED panel lights may not meet the same standards of performance, reliability, and safety. They could have inconsistent light distribution, resulting in uneven illumination and an overall poor lighting experience.

Moreover, these lights will not excel in terms of light efficiency, power factor, material, and heat dissipation. Especially the material of the LED chip and drivers will be a big gap with high-quality panel lights. The combination of these factors can lead to premature failures. Obviously, this will result in the need for frequent replacements, which will cause hassle and extra expense in the long run.

Furthermore, low-quality panel lights may not adhere to safety regulations, posing potential risks and hazards. In particular, the use of a non-isolated drive power supply can make the safety hazard greater. So, it’s crucial to prioritize high-quality LED panel lights to ensure optimal performance, longevity, and safety.

To ensure high-quality LED slim panel light, one of the crucial steps is selecting the right components. The components used, such as LED chips, driver, panel materials, and housing, play a significant role in determining the overall performance and reliability of the lights. Opting for high-quality components ensures better light output, longer lifespan, and improved efficiency.

LED chips are the heart of LED panel lights, responsible for producing the light. When choosing LED chips, there are a few factors to consider.

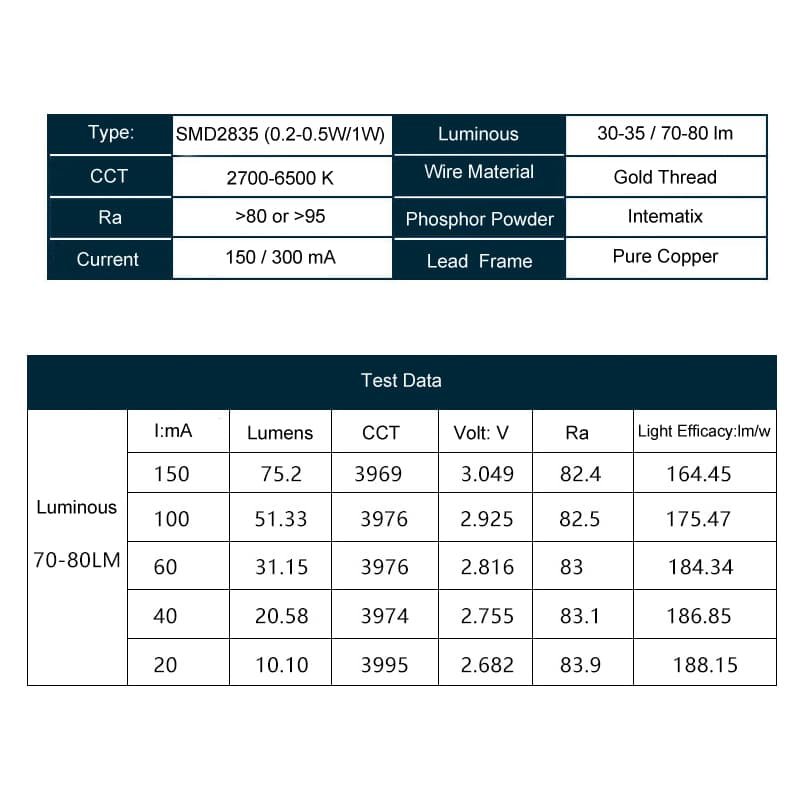

Firstly, look for chips from reputable manufacturers known for their quality and reliability. LayviKay LED panels to use Samsung, Osram, and Epistar chips, the following are our regular SMD 2835 parameters.

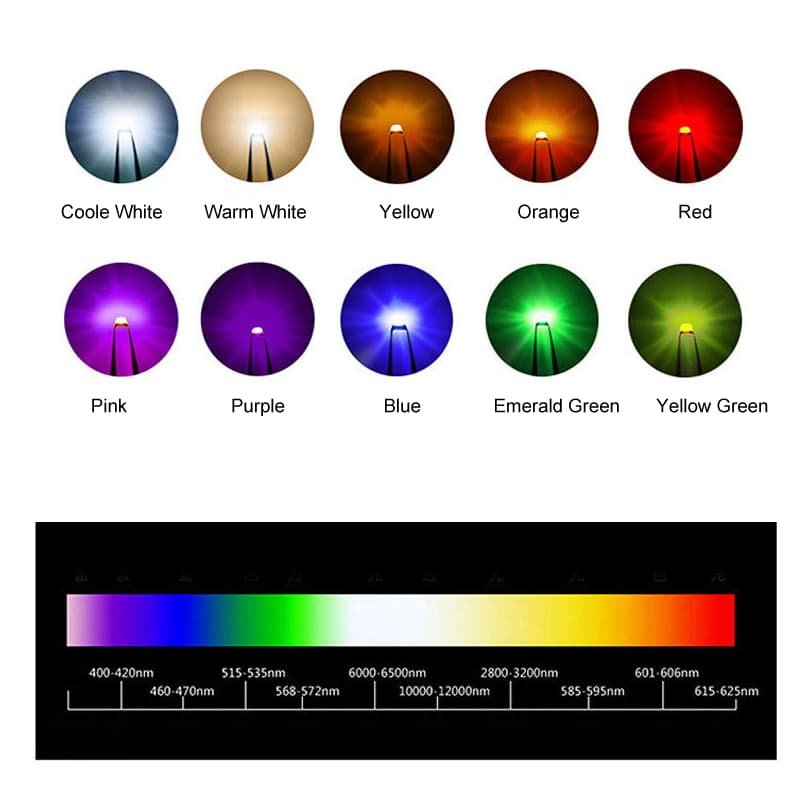

Additionally, consider the LED chips’ color temperature and color rendering index (CRI). Color temperature affects the perceived warmth or coolness of the light, while a higher CRI indicates better color accuracy.LED flat panel light with low blue light is more suitable for campus use and can reduce visual fatigue.

Finally, pay attention to the lumen output, as it determines the brightness of the LED ceiling panel light. LayviKay typically uses 70-80 lumen rated lamp beads or can be customized to the brightness you need to provide the best cost-effective solution for your project.

The materials used for the panel, housing, and driver of panel lights LED are essential for both performance and durability.

LayviKay uses a high-quality PS diffusion board. It is characterized by high light transmission, uniform diffusion, and resistance to yellowing.

As for the housing, LayviKay selects 6063 Al materials that are good at heat-dissipating, sturdy, and resistant to damage. For more about the heat-dissipation, please visit this article: https://www.layvikay.com/some-essential-elements-of-cost-effective-heat-sink/

Also, the driver is one of the main factors affecting the lifetime of panel lights. LayviKay uses isolated drive power supplies with high power factor.

For more about isolated drivers please visit our other article : https://www.layvikay.com/why-use-an-isolated-driver-in-your-led-light/

Furthermore, core materials such as electrolytic capacitors and transistors are well-known brands, which significantly extend the lifetime.

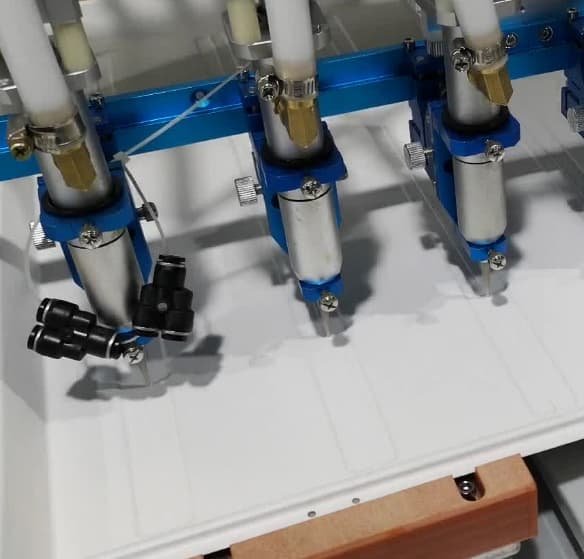

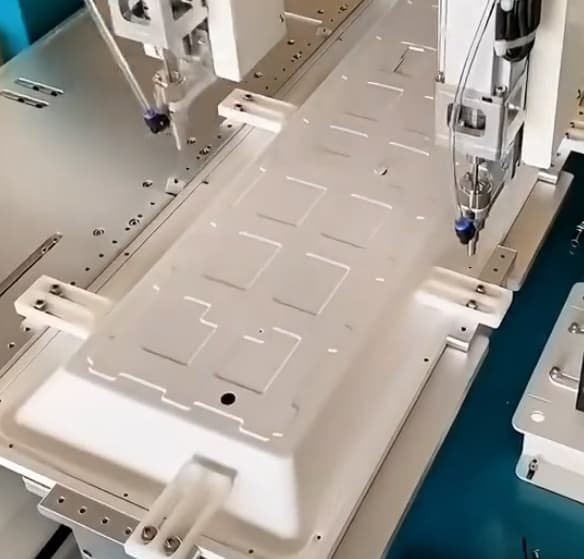

Manufacturing high-quality LED panel light requires the right assembly method. The assembly process involves integrating selected components into the final product. This includes mounting the LED beads onto the PCB, fixing the PCB board to the aluminum frame, connecting the electrical components, and installing the light guides, reflective paper, and back plate.

We use fully automated equipment for production, such as SMT machine, wave-peak soldering machine, automatic gluing machines, automatic drying machines, and automatic screw-locking machines. These types of equipment can accurately assemble the finished products and effectively avoid manual errors, thus improving the quality stability of the whole batch of goods.

There are some production processes such as soldering wires to shaped parts and installing clips that cannot be automated. These processes require the use of skilled employee.

Skilled employee and training are essential to ensure the proper assembly of LED light panel. LayviKay employees are trained and tested quarterly on assembly procedures, and most have more than 3 years of production experience. This helps minimize errors and ensures consistency in the manufacturing process, resulting in high-quality finished products.

Testing and inspection procedures are vital to ensure the high quality of LED panel lights. These procedures involve rigorous checks at various stages, from incoming components to the final assembled product.

Testing may include checks for electrical performance, light output, color accuracy, thermal management, and safety compliance. These parameters include real power, light efficiency, color temperature, CRI, power factor, flicker rate, and insulation resistance. Testing these parameters helps verify that the LED panel lights meet the required standards and perform as expected.

LayviKay has a complete set of test equipment, including a photoelectric test integrating sphere, luminous intensity distributions test instrument,

resistance instruments, EMC instrument, and comprehensive tester for insulation performance. These instruments are able to do sample testing on mass-produced panel lights to ensure that all parameters meet customer requirements.

Aging is an important part of the testing that all LED panel lights must pass.It usually includes low voltage aging (85V), normal pressure aging (220V), high voltage aging (280V), and shock aging (50-300V).

During the aging process, there will be some dead light(not bright) phenomenon, which can detect the potential defective products and thus improve the quality of the whole batch of LED lights.

In conclusion, LayviKay adopts comprehensive and meticulous quality management throughout the manufacturing process, with mature automated equipment and excellent technical staff, to ensure that each piece of ultra thin LED panel light meets customers’ requirements.

By prioritizing quality at every step, we can create a brighter and more sustainable future with high-quality LED panel lights.

High-quality LED panel lights offer numerous benefits such as superior performance, energy efficiency, and longer lifespan. They provide reliable and consistent lighting, reducing the need for frequent replacements and maintenance. Moreover, high-quality LED panel lights comply with safety regulations, ensuring a secure lighting environment.

Low-quality LED panel lights may exhibit signs such as inconsistent lighting output, flickering, or premature failure. They may also have poor color accuracy(low Ra value), higher energy consumption, and inadequate heat dissipation. There are also common occurrences such as the yellowing of diffusion panels, low light efficiency, and poor sealing that lead to flying insects getting in.

Low-quality panel lights often use low-lumen rated lamp beads, and the whole light efficiency is below 80LM/W, resulting in a poor user experience.

LayviKay adopts high-lumen lamp beads of famous brands, and the whole light efficiency reaches more than 150 LM/W. Therefore, adopting high-lumen grade lamp beads is an effective way to improve light efficiency.

Regarding light loss, improving the transmittance of the light guide and diffusion plate is an effective way to reduce light loss. At the same time, it is also necessary to adjust the distance between the aluminum substrate and the diffusion plate to find the best balance between brightness and luminous uniformity.

Can You Charge A Solar Panel With An Led Light? Solar panels and LED lights have revolutionized the way we harness and utilize energy. Solar panels, with their ability to…

Professional Power Amplifier Purchasing Guide Whether for commercial or home use, professional power amplifier is a kind of audio equipment with high cost performance. LayviKay, as a reliable audio factory…

The Basic Guide to All In One Solar Street Light Streetlights are important to improve people’s quality of life at night in public spaces. Setting up street lights can be…

Why Solar Light Batteries Need Overcharge and Overdischarge Protection? Have you ever wondered why the batteries in solar lights require an overcharge and overdischarge protection feature? These safety measures aren’t…

What Is The Best Solar Pillar Light On The Market? The “best” solar pillar light can vary depending on your specific needs, preferences, and the desired style for your outdoor…

LED Panel Lights: The Preferred Solution for Hospital Lighting The right hospital lighting design plays a crucial role in providing visibility, enhancing color rendering, minimizing glare, promoting patient well-being, and…