All Need to Know About Lifespan in Your LED Lighting Projects

LED lighting has become mainstream in a variety of lighting applications due to its high energy efficiency and environmental friendliness compared to traditional lighting solutions. Before an LED lighting project enters the design and purchasing process, a thorough understanding of the optimal performance and lifetime of LED lamps is an important factor in its success.

In this article, we will look at the key factors affecting the life of LED lamps, including LED drivers, heat dissipation, and LED beads, as well as how to optimize lamps to increase their lifespan and thus reduce the frequency of replacement.

Understanding the Lifespan of LED Lamps

Unlike traditional fixtures that have a limited lifespan, the actual lifespan of an LED lamp is much longer. The lifespan can be expressed as the ability of this LED fixture to maintain a certain percentage of its initial brightness throughout its lifetime.

To illustrate, let’s consider a hypothetical situation where an LED lamp has an initial lumen output of 1,000 lumens and then begins to depreciate at a rate of 10% per year. After one year, the brightness will drop to 900 lumens, and after two years, the brightness will drop further to 810 lumens. Over time, the brightness will decline until it reaches a point where the light output is too dim to use.

Poor Performance in Lumen Attenuation

Lumen degradation not only affects the visual quality of lighting but also its energy efficiency. As an LED lamp becomes less bright, it may no longer be able to provide enough light for its intended application. This can lead to reduced visibility and compromised safety in areas such as streets, parking lots, or commercial spaces.

In addition, as the lumen output decreases, the LED light may require an additional light source to compensate for the loss of brightness. This not only increases energy costs but also reduces the overall energy efficiency of the lighting system.

To ensure the longevity of your LED lamps and maximize energy savings, it is critical to understand and address the factors that affect lumen maintenance. In this article, we will look at these factors, including the impact of temperature on LED performance, and the importance of optimizing drive current to improve durability. Please note that this section provides a brief overview of LED lamp life and lumen maintenance. Subsequent sections will delve deeper into each topic, providing more detailed information and practical insights.

Test Methods and Standards for Evaluating LED Lamp Lifespan

Test Methods

Long-term lifetime tests and environmental simulation tests are two different types of methods to evaluate the lifespan, they have different advantages and disadvantages.

Long-term lifetime tests can more accurately reflect the performance degradation of LED lamps in actual use, but the test time is longer; while the environmental simulation test can assess the life of LED lamps in a shorter period, but the test results may differ from the actual use of the situation. Therefore, in the actual application, it is necessary to choose the appropriate test method according to the specific situation.

-

Long-term Life Test:

In a laboratory environment, the LED light sources are allowed to run continuously for a certain period (e.g. 1000 hours) and the measured optical power or luminous flux is the initial value. The luminous power or luminous flux is measured as the initial value. Afterwards, the luminous flux decay is measured by applying the rated current, to evaluate the lifetime.

-

Environmental simulation test:

Simulate various environmental conditions (e.g. temperature, humidity, air pressure, etc.) that LED light sources may encounter in the laboratory to accelerate the aging process of the lights. In this way, the life of the LED lights can be evaluated in a shorter period.

LED Panel Light Aging and Testing Process

Test Standards

The lifetime of an LED light is evaluated through industry standard tests such as TM-21 and LM-80.

-

IES-LM-80:

This is a standard published by the Illuminating Engineering Society (www.ies.org) for testing the life and lumen maintenance of LED light sources. The light source is required to operate continuously for at least 6,000 hours at the test temperature (usually 55°C), and the test frequency is every 500 hours to record data such as luminous flux, current, and optical characteristics to evaluate the light source’s performance in terms of light degradation.

-

IES-TM-21:

This standard was developed in support of IES-LM-80 and provides predictions of the light decay of light sources by deriving experimental data and converting it to predictive data. Using TM-21, it is possible to predict the light decay of a light source at a certain time in the future, based on test data from IES-LM-80. It uses this information to predict the L70 lifetime, the point at which the initial lumen output of an LED decays to 70%.

Data Metrics

The two data metrics used to estimate LED lamp lifetime are the L70 and LxxByy reports.

-

L70 Lifetime:

This represents the point at which the lumen output of an LED lamp decays to 70% of its original brightness. In other words, it represents the time it takes for an LED lamp to reach a level where it still functions properly but has lost some of its original brightness. l70 is often used as a standard measurement to estimate the lifetime of an LED lamp.

-

LxxByy Report:

It provides information on how well the luminous flux remains constant over time. the “L” value indicates the minimum luminous flux that is maintained for a specific period, while the “B” value indicates the margin of error or the amount of time it takes for a certain percentage of LEDs to reach a specific percentage of their original luminous flux at the maximum ambient temperature.

For Example:

-

L80B10:

This means that after 50,000 hours (about 16 years) the luminaire will emit less than 80% of its original luminous flux, but at least 90% of the LEDs will maintain more than 80% of their original luminous flux.

-

L70B50:

In this case, the luminaire will maintain more than 70% of its original luminous flux for 50,000 hours, but only 50% of the LEDs will maintain this luminous flux.

These metrics help determine acceptable lifetime measurements for LED light sources in different applications. For example, indoor lighting typically requires 80% maintenance, while street lighting requires at least 90%.

The Role of LED Drivers and Optimization

The Role of the LED Light Driver

The main role of the LED driver power supply is to convert the external power supply into a specific voltage and current to drive the LED lighting products to emit light and carry out the corresponding control. It plays a key role in enhancing the luminous efficiency, product stability, reliability and service life of LED lighting products, and profoundly affects the performance and quality of LED lighting products.

The role of LED driver power supply includes the following aspects:

-

Voltage Conversion:

LED lights need specific voltage and current to emit light normally, so LED driver power supply needs to convert utility power into voltage and current suitable for LED lights.

-

Brightness Adjustment:

The dimmable LED driver power supply has a brightness adjustment function, which can adjust the brightness of LED lights as needed to meet different lighting needs.

-

Protection Function:

LED driver power supply also has the function of over-current protection, over-voltage protection, and short-circuit protection, which can protect the LED lights from being damaged because of too much current or too high voltage.

Summary Table of LED Driver Features, Functions, and Performance Metrics

| LED Driver Feature | Description and Importance |

|---|---|

| Efficiency | Highly efficient drivers consume less energy and help minimize heat build-up, reducing stress on the LED chip and extending its lifespan. |

| Current and Voltage Stability | Consistent current and voltage to the LEDs ensures a stable and uniform light output. |

| Dimming | Dimming capabilities help reduce energy consumption and offer greater control over light output. |

| Protection Functions | Short circuit, overvoltage, and over-temperature protection can prevent damage to the LEDs and the driver. |

| Performance under Varying Conditions | A high-performance LED driver can ensure stable operation under a range of conditions, including temperature and voltage fluctuations. |

Optimizing Drive Current

The current that powers an LED not only determines its brightness but also plays a key role in its durability. Excessive drive current can cause LEDs to age faster and have a shorter life. Too little current reduces the performance of the entire luminaire. Therefore, ensuring stable and precise control of the current is one of the key factors to improve the life of the luminaire.

Regular Control Schemes for Dimmable Light Drive Current:

-

PWM Control:

It is a method to control the LED brightness and current by adjusting the pulse width. Since the human eye’s response to brightness is an integral effect, precise control of LED brightness can be realized by quickly switching the LED and adjusting the length of switching time to regulate the brightness. The advantages of this method are high control accuracy, fast response speed, and dynamic dimming can be realized.

-

Digital Control:

It is a method of using digital chips such as a micro-controller or digital signal processor to adjust LED current by writing a control program. This method can realize precise current control and has programmability and high flexibility, suitable for LED lamps and lanterns that need intelligent control.

Regular Control Schemes for Non-dimmable Drive Currents

-

Regulated power supply:

control the current by stabilizing the voltage, and keeping the current within a certain range, to prolong the life of LED lights.

-

Constant Current Power Supply:

By keeping the current constant, preventing the current from being too large or too small to cause damage to the LED lights, and at the same time extending the life of the LED lights.

-

Switching Power Supply:

Control the brightness of the LED light by fast switching, thus adjusting the current size and prolonging the life of the LED light.

Regardless of the control method used, the operating current of the LED lamp bead must be within the specified rated range. Next, we will discuss common current limiting techniques used in LED circuits to enhance the overall life of the LED lamp.

Forward Voltage and Forward Current in LEDs

An LED’s anode and cathode are connected when it is forward-biased, or activated. In the LED’s semiconductor junction, electron-hole complexation takes place when there is a forward bias. The LED releases energy as light due to the electron-hole complexation. The spontaneous emission of light is caused by the electrons moving from the high energy band to the low energy band. In reverse bias scenarios, LEDs are unable to produce light. Depending on the semiconductor compound utilized, LEDs operating under forward bias circumstances produce different colors of light.

LEDs are current-dependent devices, meaning that the semiconductor material affects both the forward voltage and forward current. LEDs are distinguished by their forward voltage and forward current, just as signal diodes. The forward voltage and forward current are typically between 1.2 and 3.6 volts and 10 and 30 milliamperes, respectively.

One crucial curve in the LED datasheet is the forward current to voltage (I-V) characteristic. To see why it must limit the current in LEDs, let’s look at their I-V characteristics.

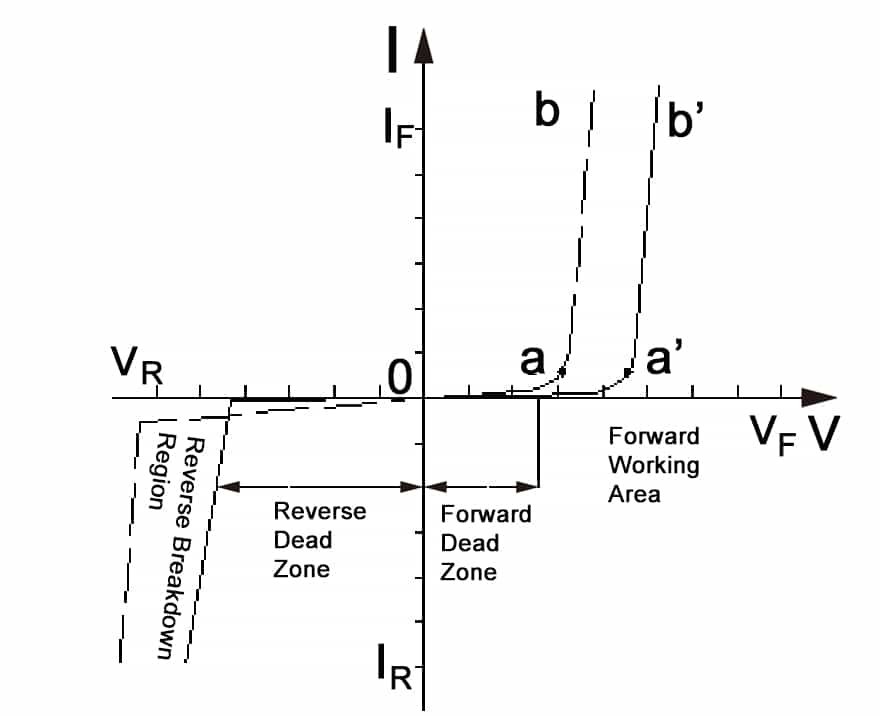

I-V Characteristics of LEDs

The I-V characteristic of an LED describes the current through it at different applied voltages. The forward LED current is plotted as a function of voltage. The I-V characteristics of LEDs follow a non-linear pattern, which is contrary to Ohm’s law. According to Ohm’s law, there is a linear relationship between current and voltage. In this linear I-V characteristic, the current increases as the voltage increases.

For example, a resistor is a linear circuit component that obeys Ohm’s law. In a resistor, the ratio of voltage to current is always equal to the value of the resistance. However, LEDs are not governed by Ohm’s law. The current drawn is very low until the voltage applied to the LED reaches the forward voltage. When the applied voltage exceeds the forward voltage value, the current increases exponentially with voltage. Excessive current flow through LEDs destroys them immediately, so it is necessary to limit excessive current flow. Below is a graph of the I-V characteristics.

How to Limit Current in LEDs

It is crucial to limit the current in any LED circuit. The LED forward current value for a particular light intensity can be found using the I-V characteristic. Any current limiting method aims to keep the LED’s current within the selected range. Here are a few regular techniques for limiting current in LED circuits.

Type 1:

LED circuits in parallel LEDs with the same color can be seen connected in parallel in lighting circuits. Each branch’s current draw is determined by its internal resistance. Only when LEDs of the same color are linked in parallel does this technique function. The LED with the lowest internal resistance draws greater current when colors are mixed, which might lead to burnout or a shorter lifespan.

Type 2:

Upholding the specified positive voltage value listed on the specification sheet for the LED The voltage applied from a stabilized DC power source can be changed to keep the voltage of the LED within the positive voltage range. This could change how bright the light is. It is easy to set the voltage to the forward voltage value if the user is happy with the output light intensity.

Type3:

Power supply intended specifically for LED applications are called constant current LED drivers. Constant voltage and constant current LED drivers are the two different kinds of LED drivers. A constant current LED driver limits the drawn current to a predetermined value by varying the power supply’s voltage over a range.

Type4:

LEDs are linked in series with current limiting resistors. LED circuits can be configured with current limiting resistors in both series and parallel configurations.LED current limiting resistors function by keeping the LED’s current within a predetermined range that is listed in the datasheet for the LED as safe forward current. Certain known characteristics, such supply voltage (V_supply), forward current (I_LED), and forward voltage (V_LED), are used to calculate the value of the current limiting resistor. The value of the current limiting resistor (R_LED) can be given by the following formula:

LED current limiting resistor R_LED=(V_supply-V_LED )xΩ/I_LED

Once you understand the value of the forward current required to provide the desired light intensity output, it is simple to limit the current of the LED. You can use Cadence’s PCB design and analysis tool to design LED circuits with current limiting. For this analysis tool please visit: www.cadence.com

Optimizing drive current is one aspect of them, and many other parameters and protection features are important to the drive’s lifetime, which we will explore one by one in future articles.

Role and Optimization of Heat Sinks

While drive current is an important factor in LED lifetime, excessive heat buildup can also significantly shorten the life of the LED chip.

The Role of Heat Sinks in LED Lamp Life

The heat sink, which removes the heat from the LED, ensuring that the chip operates within its rated temperature range. Effective heat sink design helps to minimize thermal resistance, increase airflow, and prevent damage from overheating, all of which help to extend the life of LED lighting.

How to get the best out of your radiators

Heat sinks come in different shapes, sizes and materials. The most common designs include passive passive heatsinks that are passive, active heatsinks, and hybrid heatsinks. Passive heatsinks are simple in design and have a large surface area to dissipate heat naturally, while active heatsinks use fans or other cooling devices to help dissipate heat. Hybrid heatsinks combine passive and active cooling mechanisms for optimal heat dissipation.

For more details, please refer to this article: https://www.layvikay.com/some-essential-elements-of-cost-effective-heat-sink/

Using Reliable LED Beads

One of the key factors affecting the life of LED lighting is the quality of the LED beads. The LED chip is the core component, and high-quality LED chips last longer and perform better than low-quality chips. The following 3 aspects need special attention:

-

Photo-electronic Performance:

The Photo-electronic performance of LED chips is directly related to the brightness, color, and stability of the lamps. Well-known brands of LED chips can provide more stable brightness and color performance, thus extending the service life of the lamps. For example, the use of high brightness, and high color rendering index of the Cree chip can ensure that the lamps and lanterns in a long time after use can still maintain a high light output and color consistency.

-

Thermal Management:

LED chips in the light-emitting process will generate heat, if the heat can not be effectively dispersed, it will lead to chip temperature rise, affecting its photoelectric performance and service life. Therefore, the thermal management ability of LED chips is crucial to the life of the lamps. LED chips with efficient heat dissipation design can quickly transfer the heat generated to the lamp shell or heat sink, and maintain a low operating temperature, thus improving its life.

-

Reliability:

The reliability of the LED chip determines the overall stability of the light. In the production process of LED chips, there are some unstable potential factors for small manufacturers, such as material purity, process control, encapsulation process, and so on. The use of well-known brands of chips helps to improve the reliability of LED beads, thus extending the service life of the lamps.

“When working with LED chips, it is essential to choose high-quality components that can withstand various operating conditions. Furthermore, selecting a compatible LED driver ensures optimal performance and maximum lifespan for your LED lighting projects.”

Avoid Some Mistakes that Can Shorten the Lifetime

In actual use, LED lights need to avoid some common mistakes, which will also help to improve the service life of LED lights.

Poor electrical contact

LED lights are sensitive to current fluctuations, and poor contact can lead to voltage drops or power surges. Make sure all electrical connections are strong and wires are well insulated. To avoid such problems, all high-voltage fixtures must be installed by a professional electrician.

Inadequate ventilation

LED lamps generate heat, and without proper ventilation, heat can build up and lead to a shortened lifespan. Avoid installing LED lamps in enclosed areas where heat cannot be dissipated effectively, such as recessed lighting fixtures with poor airflow.

IP rating can not meet the environmental requirements

The IP rating is the main standard to measure the waterproof performance of LED lamps, and it can also reflect the protection performance of LED lamps.

For example, IP50 LED lamps and lanterns have dustproof performance, but waterproof performance is poor; while IP65 LED lamps and lanterns have better dustproof and waterproof performance, which can be applied to more severe environments.

Meaning of Numbers

IP rating in the number of “6” indicates that it is completely prevented from foreign objects and dust invasion, the number ” 7″ indicates that it can be completely immersed in water under certain conditions. The number “6” in the IP rating indicates complete protection against foreign objects and dust intrusion, while the number ” 7″ indicates that it can be completely immersed in water under certain conditions.

Therefore, IP65, IP67, and IP68 have different waterproof performance, the higher the IP rating, the better the dustproof and waterproof performance of the LED lamps and lanterns, and they can be used in more severe environments.

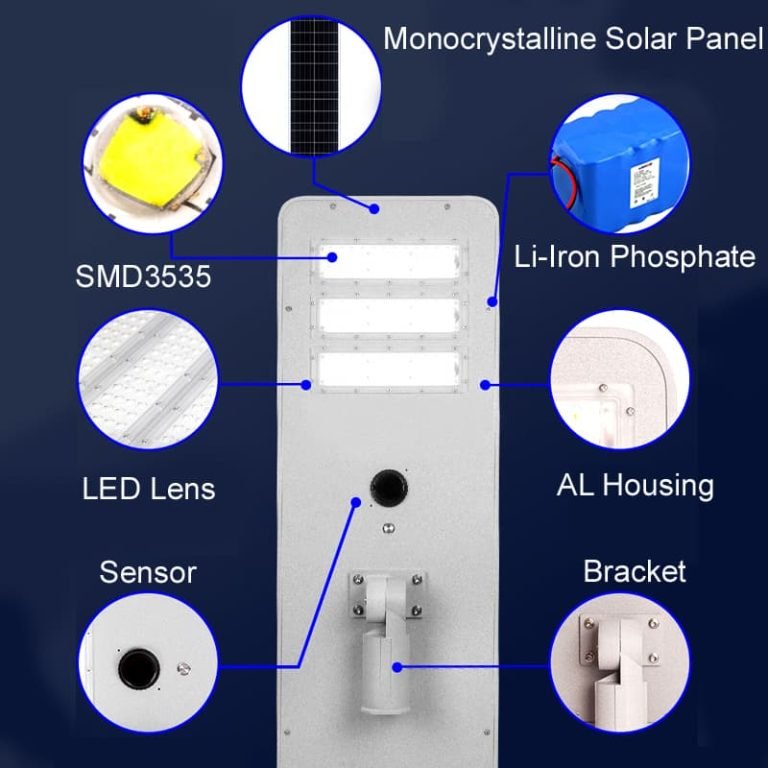

Examples from LayviKay

For example, IP65-rated LED panel light can withstand water spray in all directions, but cannot be fully immersed in water. IP67-rated solar street light can be completely immersed in water within a certain period, suitable for a more humid environment. IP68-rated wall washer light can withstand prolonged immersion in water, suitable for underwater lighting and other special environments.

Regular Testing of IP Grade and Aging

Before your designing or purchasing, you must consider whether the IP rating meets the requirements of various environments, including dust, humidity, etc. LED luminaires with high IP ratings can better adapt to a variety of harsh environments. For example, in environments with high humidity such as bathrooms or kitchens, choosing IP65 or higher-rated LED luminaires can ensure their waterproof performance and avoid damage caused by moisture intrusion.

Summary

Before planning or purchasing LED lighting products, it is critical to consider lifetime factors such as LED driver technology, heat dissipation methods, and LED chip quality. It is also important to avoid some common mistakes.This is important to extend the life of LED lighting, reduce maintenance costs, and improve the reputation of the project.

With careful consideration of the factors discussed in this article, project managers will be able to complete projects with high quality and cost-effectiveness.